Heavy Duty Screen Printing Heads

Including Side Clamp Heads

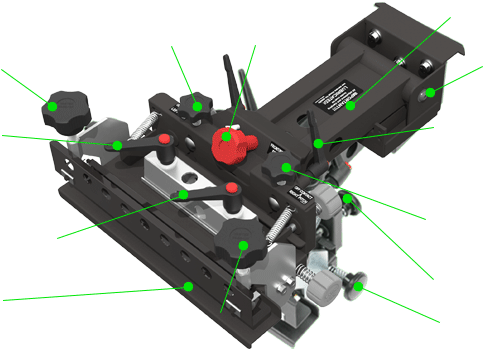

- SIX-WAY LEVELING AND

OFF-CONTACT KNOBS

- SCREEN CLAMP KNOB

- REPOSITIONABLE

LOCKING LEVER

(FOR MICRO

REGISTRATION

ADJUSTMENT)

- REPOSITIONABLE LOCKING

LEVER (FOR MICRO

REGISTRATION ADJUSTMENT)

- SUPER HEAVY DUTY

SCREEN CLAMP

- RIGID EXTENSION ARM

- HINGE PIN

- REPOSITIONABLE LOCKING

LEVER (FOR LEVELING AND

OFF-CONTACT ADJUSTMENT)

- SIX-WAY LEVELING AND

OFF-CONTACT KNOB

- MICRO REGISTRATION KNOB

- MICRO REGISTRATION KNOB

- SCREEN CLAMP KNOB

SLASHES SET-UP TIME, BOOSTING PROFIT

- SIX-WAY LEVELING AND OFF-CONTACT KNOBS

- All knobs for six-way leveling and off-contact adjustments are positioned on the top of the head for easy access

- Center red knob tilts the head (screen) "fore and aft".

- Two black knobs flanking the red knob tilt the head (screen) up and down on the left and right sides respectively, compensating for warped screens and leveling the screen to the pallet.

- Rotating both black knobs by the same amount moves the screen up and down to increase or decrease the off-contact (distance between the screen and the pallet).

- The print head always locks into the "gate" at the same position, allowing off-contact adjustment with no change in the angle or position of the screen relative to the pallet.

- SCREEN CLAMP KNOBS

- Massive Hand Knobs with posts threaded a full inch (254 mm) into heavy-duty clamp bar brackets secure screens instantly with no tools. (Side clamps also available)

- REPOSITIONABLE LOCKING LEVERS (FOR MICRO REGISTRATION ADJUSTMENT)

- Two levers shown are used to free the head, allowing micro registration adjustments (described above), and to then lock the head into its new position — instantly, with no tools.

- Repositionable feature of locking levers allows you to lift the lever to select a new position, and lock it into the new position by lowering it, to better operate in limited spaces that prevent full rotation of the lever and/or for ergonomics.

- SUPER HEAVY DUTY SCREEN CLAMPS

- 12 in. (305 mm) wide, Super Heavy Duty Steel Clamps of 1/4 in. (6.35 mm) thick steel, hold screens securely, and allow off-center clamping.

- MICRO REGISTRATION KNOBS

- Anti-backlash micro registration side knob (for side-to-side movement) and two lower knobs (for front-to-back and rotation) move the screen in any horizontal direction, up to 1/4 in. (6.35 mm) from the neutral or "home" position.

- Adjustments have no slop or play, allowing you to know in advance how much to rotate a knob to register the head. For example, a one-quarter turn moves the print head precisely .015" (1/64"), a one-half turn precisely .031" (1/32") and a full turn precisely .062 (1/16" or 1.5 mm).

- REPOSITIONABLE LOCKING LEVERS (FOR LEVELING AND OFF-CONTACT ADJUSTMENT)

- Two levers shown are used to free the head, allowing off-contact and/or leveling adjustments (described above), and to then lock the head into its new position — instantly, with no tools.

- Repositionable feature of locking levers allows you to lift the lever to select a new position, and lock it into the new position by lowering it, to better operate in limited spaces that prevent full rotation of the lever and/or for ergonomics.

- HINGE PIN

- Ground and polished, with anti-backlash bearings

- RIGID EXTENSION ARM

- Designed to support a 7 ft (213 cm) wide, 50 lb (23 kg) numbering system!

OPTIONS

- Side clamps, three lengths 8" 12" and 30"

- DiGiT: The industry's fastest numbering system

- Pin Registration System for Side Clamp Presses

Remember: It's set-up time — not printing speed — that dictates your output and your profit, and no other press cuts your set-up time as dramatically as a Vastex.

Radically different from competitive systems, the Vastex micro-registration print head adjustment is:

- spring loaded

- anti-backlash

- direct drive

- supported from an ultra-rigid frame

As a result, rotating the knob 1/4; turn moves the print head precisely .015" (1/64"), with a 1/2; turn moving the print head precisely .031" (1/32")... every time... and always in a straight line, whether your press is brand new or 10 years old. This extreme predictability, with zero slop or play, means you know — in advance — how much to rotate a knob to move the head into registration.

By contrast, virtually all competitive print heads use turnbuckles (without spring loading) to move the print head, with two negative results: First, as the machine wears, the amount of screen movement per rotation of the turnbuckle can vary, causing the operator to A) estimate how much to rotate the turnbuckle to align one of the colors B) make that movement and lock the head C) print another sample and find it did not move where expected, and D) discard that shirt or test square and try it again.

Worse, turnbuckles cause the head to pivot left-to-right in an arc, instead of moving in a straight line, adding to the difficulty of guessing where the head will move.

Multiply the extra time and rejects by the number of colors, and turnbuckles can waste 15 to 30 minutes every time you "Dial-in" a job — time you could be printing garments and making profits!

For blazingly fast multi-color set-ups, add a Vastex Registration System to your press, and print more garments per hour than ever before possible, by far.

Click on the blue Live Chat tab on the right to speak to a Vastex representative.

(Available daily 9:00 AM - 5:00 PM EST, Monday - Friday)

Or click here to REQUEST A QUOTE >>