Cure screen-printed plastisols, water-based inks

discharge and/or DTF adhesives at high rates

(For curing of DTG-printed garments see LittleRed® D Series and BigRed® D Series Dryers)

EconoRed II dryers in 30 and 54 in. (76 and 137 cm) belt widths cure garments screen-printed with plastisol, water-based inks and discharge, and/or DTF adhesives at high rates. The modular design allows for expandability to easily add chambers and conveyor length as production needs increase.

Model ER-II-30 with 30 in. (76 cm) wide belt and two 24 in. (61 cm) wide heaters (total 7,200 watts) cures up to 300 plastisol-printed garments/h, or 100 garments/h screen-printed with water-based ink or discharge.*

Model ER-II-54 with 54 in. (137 cm) wide belt and two 48 in. (122 cm) heaters (total 14,400 watts) cures up to 600 plastisol-printed garments/h, or 200 garments/h screen-printed with water-based ink or discharge.*

A top-mounted ventilation system filters exhaust air, cools the enclosure's outer skin, and evacuates moisture and fumes from the heating chamber. It also makes ER-II dryers over 20 percent quieter and 5 in. (13 cm) narrower, and allows the control box to be positioned the right side (standard) or left side of the enclosure to suit shop layouts.

Using a damper control knob, the user can adjust the volume of exhausted air from 100% to 10% to remove all fumes emitted in the heating chamber according to the size, weight, throughput and ink type of DTG and screen-printed garments, and/or the dwell time needed to cure powdered adhesives of DTF images or screen-printed transfers. Excess air flow unnecessary for exhausting of fumes is diverted and filtered to cool the double-wall skin of the heating chamber for worker safety.

All heaters feature closely spaced coils that provide high-density, medium-wavelength infrared heat for maximum cure speed without cold spots or under-curing, and come with a 15-year warranty.

The Vastex Infrared Focusing System allows heater adjustment to any height from 2 to 7 in. (5.1 to 17.8 cm) above the belt, allowing the operator to compensate for bulky garments or hats, and can be customized to provide additional heater clearance.

All models include a digital belt speed display and a belt tracking system for increased belt life. The digital PID temperature controller is accurate to +/- 1°F (+/-0.5°C), allowing the operator to fine-tune or accurately repeat drying results at any future time.

BELT WIDTH

30" (76 cm) or 54" (137 cm)

HEATER WIDTH

24" (61 cm) or 48" (122 cm)

MAXIMUM IMAGE WIDTH

18 in. (46 cm) or 42 in. (107 cm)

(Heater width minus 6 in. [15 cm])

ADVANCED

Top-mounted, Focused Exhaust Air System evacuates fumes and moisture quickly

ADJUSTABLE

Damper control knob modifies exhausted air flow from 100% to 10% to optimize curing of garments, transfer films and DTF adhesives

QUIET

20% quieter than earlier models

HEAVY DUTY

"X-Series" Conveyor Belt Tracking System

FOCUSED

Infrared Focusing System allows 2 - 7 in. (5 - 17.7 cm) belt-to-heater height adjustment to accommodate hats or bulky garments, and can be customized to provide additional heater clearance.

ACCURATE

Temperature controller accurate to +/-1°F (+/-0.5°C)

Digital PID with fuzzy logic — industry's most advanced

CONSISTENT

Heavy duty DC belt speed motor with digital voltage display

INNOVATIVE

Shorter, slimmer and quieter with high heat and production

EXPANDABLE

Add heat chambers at 36 in. (91 cm) long each, and 18 in. (46 cm) belt extensions, front or rear

Modular expandability allows your dryer to grow with you

The capacity (belt speed) of all Vastex floor standing conveyor dryers can be doubled or tripled as new or when needs increase by simply adding one or two modular heating chambers and extending the conveyor belt. This eliminates the need to invest in a larger dryer than you need at the onset, and avoids the high cost of purchasing a new dryer when your needs increase.

OPTIONS

- Heating chambers @ 36 in. (91 cm) long

- Belt extensions, front or rear @ 18 in. (46 cm) long

- Control box on left side (right side standard)

- 240, 400 and 480 voltages

- Exhaust hood for extra fume extraction

- Hat support rail

- Locking casters for mobility

- Reversing belt/HD Drive

- Additional heater clearance

- Retrofit kits are available for upgrading existing EconoRed dryers with the adjustable exhaust damper.

Vastex EconoRed Series Dryers allow adjustment of exhaust air flow to maximize curing efficiency for each application, while saving energy and cooling the enclosure skin for operator safety.

* Rated Shirts/hr are approximations and are based on certain conditions including humidity, image size, substrate material, etc.

Click on the blue Live Chat tab on the right to speak to a Vastex representative.

(Available daily 9:00 AM - 5:00 PM EST, Monday - Friday)

Or click here to REQUEST A QUOTE >>

OPTIONAL ACCESSORIES

CONVEYOR EXTENSIONS & ADDITIONAL CHAMBERS

Vastex Conveyor Extensions make it easy to increase production without buying an entirely new dryer. Extensions can be used to increase the infeed, outfeed, or add additional heat chambers. With bolt-on installation and conveyor belt extensions, your dryer can be upgraded quickly and easily.

Available belt sizes:

- 18 x 18 in. (45.7 x 45.7 cm)

- 18 x 36 in. (45.7 x 91.4 cm)

- 24 x 18 in. (61 x 45.7 cm)

- 24 x 36 in. (61 x 91.4 cm)

- 24 x 54 in. (61 x 137.2 cm)

- 30 x 18 in. (76.2 x 45.7 cm)

- 30 x 36 in. (76.2 x 91.4 cm)

- 30 x 54 in. (76.2 x 137.2 cm)

- 54 x 18 in. (137.2 x 45.7 cm)

- 54 x 36 in. (137.2 x 91.4 cm)

- 54 x 54 in. (137.2 x 137.2 cm)

- 78 x 36 in. (198 cm x 91.4 cm)

- 78 x 54 in. (198 cm x 137.2 cm)

INCREASING CAPACITY OF A VASTEX CONVEYOR DRYER

with additional heating chamber and conveyor belt extension

EXHAUST HOOD

- Exhaust booster system reduces fumes at exit of dryer (a "must have" for DTF adhesives on D1-Series and LR-X1)

- Independent power and control

- Snap ON or OFF for easy mobility and maintenance

- Diagnostic pilot light and ON/OFF switch

- Optional adjustable conveyor mount available

Model EXH-18

For dryers with belt width of 18 to 30 in. (46 to 76 cm)

- 141 cfm, 2.1 amps, NEMA 5-15P plug

- 141 cfm, 1.0 amps, NEMA 6-15P plug

Model EXH-24

For dryers with belt width of 24 in. (61 cm)

- 141 cfm, 2.1 amps, NEMA 5-15P plug

- 141 cfm, 1.0 amps, NEMA 6-15P plug

Model EXH-30

For dryers with belt width of 24 to 36 in. (61 to 91 cm)

- 141 cfm, 2.1 amps, NEMA 5-15P plug

- 141 cfm, 1.0 amps, NEMA 6-15P plug

Model EXH-54

For dryers with belt width of 48 to 60 in. (122 to 152 cm)

- 300 cfm, 1.0 amps, NEMA 6-15P plug

POWERED EXHAUST

Optional powered exhaust removes moisture and fumes — ideal for working in confined spaces.

POWERED EXHAUST

Optional powered exhaust removes moisture and fumes — ideal for working in confined spaces, especially when curing of DTF adhesives.

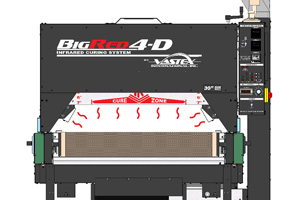

SIDE HEATERS

Side-mounted heaters can be added to any model, and come as standard on deluxe models.

- Positioned at a 45 degree angle

- Controlled from the main panel

- Available in single or three phase dryers and in 240, 380, and 480 V

- Each heater is 1,400W adding a total of 2,800W

- Digital timer adjusts heat output from 0 to 100%

- Increases "cure zone" to 24 in. on 30 in. belts

- Increases "cure zone" to 48 in. on 54 in. belts

- Side heaters can be tilted from 40 - 50 degrees to suit application

- The addition of side heaters changes the heater height adjustment range from 2 - 7 in. (5 - 17.8 cm) to 4 - 7 in. (10 - 17.8 cm)

CONVEYOR AIR BAR

- Speeds the cooling of screen-printed and inkjet-printed garments, caps, koozies, umbrellas and hard goods as they exit a dryer's heating chamber, rapidly cooling/hardening hot ink that is soft or tacky, and making printed items easy to fold or package.

- Houses tightly-spaced mini fans providing uniform airflow across the printed item, angled outward to avoid blowing cool air into the heating chamber.

- Height adjustable to accommodate thin to bulky items.

- Independent power

Model CAB-24 houses five fans, and adjusts to fit any Vastex or other dryer having a 33 to 39 in. (83.8 to 99 cm) wide conveyor. A CAB-24-240 model is available for 240V systems.

Model CAB-30 houses five fans, and adjusts to fit any Vastex or other dryer having a 33 to 39 in. (83.8 to 99 cm) wide conveyor. A CAB-30-240 model is available for 240V systems.

Model CAB-54 includes nine fans and fits any Vastex or other dryer with a 57 to 63 in. (144.8 to 160 cm) wide conveyor. A CAB-54-240 model is offered for 240V systems.

Model CAB-78 includes twelve fans and fits any Vastex or other dryer with a 81 to 87 in. (206 to 221 cm) wide conveyor. A CAB-78-240 model is offered for 240V systems.

CAB-24

- 5 fans across unit

- Vastex: 24 in. (61 cm) wide belt dryers

- Non-Vastex: 33 to 39 in. (83.8 to 99 cm) outside conveyor width

- CAB-24-240 for 240v model

CAB-30

- 5 fans across unit

- Vastex: 30 in. (76 cm) wide belt dryers

- Non-Vastex: 33 to 39 in. (83.8 to 99 cm) outside conveyor width

- CAB-30-240 for 240v model

CAB-54

- 9 fans across unit

- Vastex: 54 in. (137 cm) wide belt dryers

- Non-Vastex: 57 to 63 in. (144.8 to 160 cm) outside conveyor width

- CAB-54-240 for 240v model

CAB-78

- 12 fans across unit

- Vastex: 78 in. (198 cm) wide belt dryers

- Non-Vastex: 81 to 87 in. (206 to 221 cm) outside conveyor width

- CAB-78-240 for 240v model

RETURN BELT CONVEYOR

- Returns cured garments to the front of the dryer while they cool, ready for folding and packaging

- Allows conveyor dryer to be positioned closer to a wall without the need of a catch bin, saving space

- Positioned between two presses, shops can print the front with one press and print the back with the second press as the garment comes back off the return conveyor

- Available for LittleRed, Little Red D Series and EconoRed dryers with 30, 54 or 78 in. (76, 137 or 198 cm) wide belts

- Can also be added as a retrofit to many existing dryers

HAT SUPPORT RAIL

HR-1 Hat Support Rail

(fits EconoRed ER-II dryers)

HR-2 Hat Support Rail

(fits BigRed BR4D and ER-III dryers)

- Easily mounts to the interior of dryer

- Stationary rail for hats to leans against. This allows the front of the hat to be parallel to heating elements.

HEAVY DUTY WHEEL SET

Model WS-EC

Standard Wheel Set

- Set of 4 fits all DriBox, LittleRed, EconoRed and BigRed dryers with 30 or 54 in. (76 or 137 cm) belt widths only

- Single caster under leg will raise the dryer an additional 4 in. (10.16 cm) off of the ground. Makes moving the dryer easy for rearranging or cleaning your shop.

Model WS-E-DD

Heavy Duty Drop-Down Wheel Set

- Set of 4 fits all DriBox, LittleRed and EconoRed I dryers with 30, 54 or 78 in. (76, 137 or 198 cm) belt widths

- Sturdy casters on each side of the leg with a bracket in between. Will only raise the dryer ½ in. (1.27 cm) off of the ground. Makes moving the dryer easy for rearranging or cleaning your shop.

HEAVY DUTY WHEEL SET

Model WS-EC

Standard Wheel Set

- Set of 4 fits all DriBox, LittleRed, EconoRed and BigRed dryers with 30 or 54 in. (76 or 137 cm) belt widths only

- Single caster under leg will raise the dryer an additional 4 in. (10.16 cm) off of the ground. Makes moving the dryer easy for rearranging or cleaning your shop.

Model WS-EHD

Heavy Duty Drop-Down Wheel Set

- Set of 4 fits all BigRed and EconoRed II & III dryers with 30 or 54 in. (76 or 137 cm) belt widths only

- Sturdy casters on each side of the leg with a bracket in between. Will only raise the dryer ½ in. off of the ground. Makes moving the dryer easy for rearranging or cleaning your shop.

MOBILE EQUIPMENT STANDS, INCLUDING CASTERS

Low Cost Stands for "tabletop" infrared conveyor dryers, screen exposing units and other screen printing equipment.

Model S1-27

- Flat top to fit Vastex D100 Conveyor Dryer, and can also accommodate other compact tabletop equipment weighing up to 250 lb (113 kg).

- 26.8 in. (68 cm) H x 32.3 in. (82 cm) W x 32.3 in. (82 cm) D

- 55 lbs (25 kg)

- Shippable via UPS

Model S1-27-DEMT

- Rail mounts fit Vastex E-200 Exposing Units, and D-1000 Conveyor Dryers

- Can also accommodate other compact tabletop equipment weighing up to 250 lb. (113 kg)

- 27.4 in. (70 cm) H x 32.1 in. (82 cm) W x 30.6 in. (78 cm) D

- 60 lbs (27.2 kg)

- Shippable via UPS

ATKINS THERMAL PROBE COMPLETE KIT

(Includes controller, probe and extra wires)Accurately measure ink temperatures to profile conveyor dryers

- Constructed of temperature-resistant Teflon®, it may be used hundreds of times with-out degradation of material or accuracy of measurement.

- The wires are designed to make DIRECT CONTACT WITH THE INK. Many other temperature measuring devices are capable of reading only the temperature of the air around the screen printed item. The rise and fall of the ink temperature may be significantly different than that of the garment or the surrounding air.

- Response Time: 1 second, in liquid

- Auto Shut-off: Auto shut-off after 10 minutes of non-use

- Warranty: 5 year instrument warranty, 1 year probe

- Cable Length: 15 ft cable with Silicone outer jacket

- Certifications: NSF, CE, Rohs, Weee

- Temperature Range: -40° to 400°F (-40° to 205°C) with probe

- Temperature Accuracy: ±0.5F° (±0.3C°) over entire range at ambient temperatures between 68° to 86°F (20° to 30°C)

- Resolution: 0.1°

- Waterproof Rating: IPX7 Waterproof-rated

- Battery Life: 1800 hours typical, 2 AAA Alkaline batteries (included)

Testing Ink Temperatures

With the thermometer on and probe plugged in, place the "ring" over an inked part of a garment (or scrap piece of material) with the cross-hairs wires down. Be sure the wires are actually touching the ink. Allow the garment and probe to be fed into the dryer along the conveyor belt. The temperature displayed by the thermometer reflects the rise in temperature of the ink as it moves through the dryer. When the temperature begins to quickly decline, the probe should now have exited the dryer. Unplug the probe and allow only the lead wire to follow the probe through the dryer. DO NOT ALLOW THE THERMOMETER TO GO THROUGH THE DRYER and DO NOT PULL RING BACK as this could damage the delicate cross-hair wires.

SCREEN PRINT DONUT PROBE

The "Donut" Screen Printing Probe is specially designed to meet the needs of today's Screen Printers.

- Constructed of temperature-resistant Teflon®, it may be used hundreds of times with-out degradation of material or accuracy of measurement.

- The wires are designed to make DIRECT CONTACT WITH THE INK. Many other temperature measuring devices are capable of reading only the temperature of the air around the screen printed item. The rise and fall of the ink temperature may be significantly different than that of the garment or the surrounding air.

- Type K thermocouple surface probe for monitoring the temperature of ink or screen printing dryers

- Measures temperature from -40° to +400°F (-40° to +205°C)

- PTFE ring 3 in. (7.6 cm) in diameter supports the sensor wires

- Response time of 1 second in liquid for fast readings

- Warranty - 1 year

- Silicone-jacketed cable 15 ft (457 cm) in length withstands temperatures up to 400°F (205°C)

TEMPERATURE LASER GUN

Measures temperature of ink and/or substate.

- Measures temperatures from 0F to 716°F (-18°C to 380°C) with typical accuracy of +/- 2%

- Fixed emissivity: 0.95

Please note that a temperature gun "only" measures the surface temperature. For the most accurate results, a donut probe is highly recommended.